Our custom-made process

From geometry and design, to component choice and paint, each bike that we craft is unique, and reflects the needs and requests of its owner. Here is how the experience unfolds.

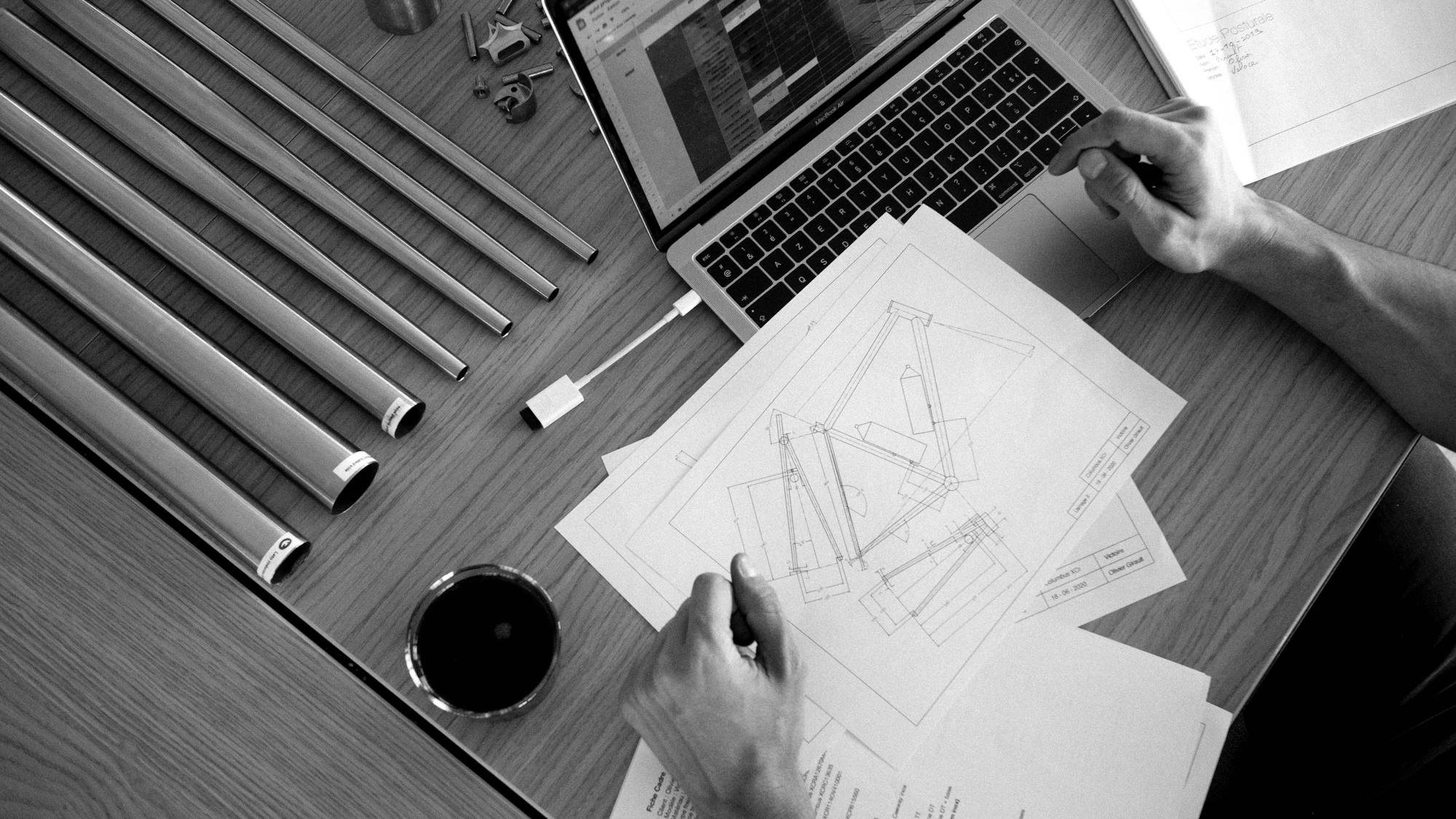

1. The project draft

Everything starts with a message or phone call. You reviewed our previous builds, you have some ideas? Tell us who you are, how and where you ride, and what you expect from your bike. From this starting point, we will clarify, shape, and quote your project draft.

After some back and forth, we will draft together the fundamentals: frame type, components, specific needs. This base project will allow us to determine the budget to build your bike.

After validating the project draft, it's time for a personal consultation with Julien, our design manager. This interview marks the end of the initial phase and serves as a baseline for the full-day, in-person appointment at our shop.

2. A day together in Beaumont

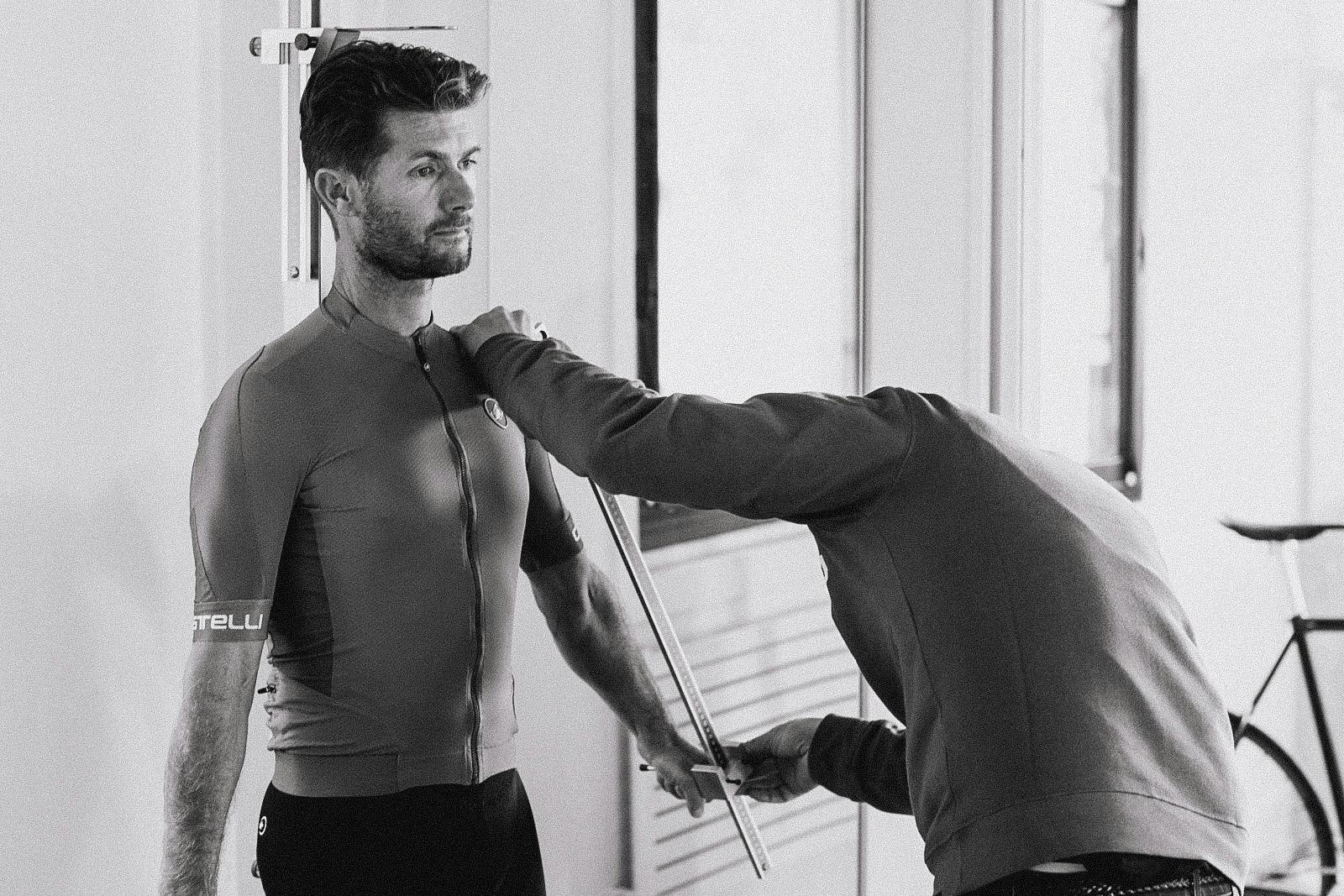

Our vision of custom bikes requires to meet in person, discuss, get to know each other, and of course, to make measurements. The second step is to spend a full day at our shop, to analyze your needs in detail, define your project further, and share with you our design principles.

By asking questions, we determine your rider profile based on your rides, your current bike, your wishes, what you like (and dislike) while riding.

The measurement is a key step. It reveals the specifies of your morphology and allows to draw a geometry draft.

The dynamic bike fitting session completes the static measurements. This phase allows to adjust the theoretical geometry and turn it into one that works with your position while in effort.

The choice of tube specifications (steel or stainless steel, diameter, range, shape, bottom bracket type, head tube type) is made based on your riding style, the results of your fitting session, and your preference in terms of looks.

Steel work offers limitless possibilities in terms of innovation and customization: internal our external cable routing, special inserts for your needs, bespoke stems and luggage-racks, special seatpost clamps, etc.

The selection of components has to match the spirit of your project. Our expertise will help you choose among the infinite options, in order to obtain a balanced, reliable and effective setup.

At last, we discuss together to decide your bike's paint job: colors, transitions, logos, etc.

Following this meeting, your project specifications are final and your bike is placed in queue for production.

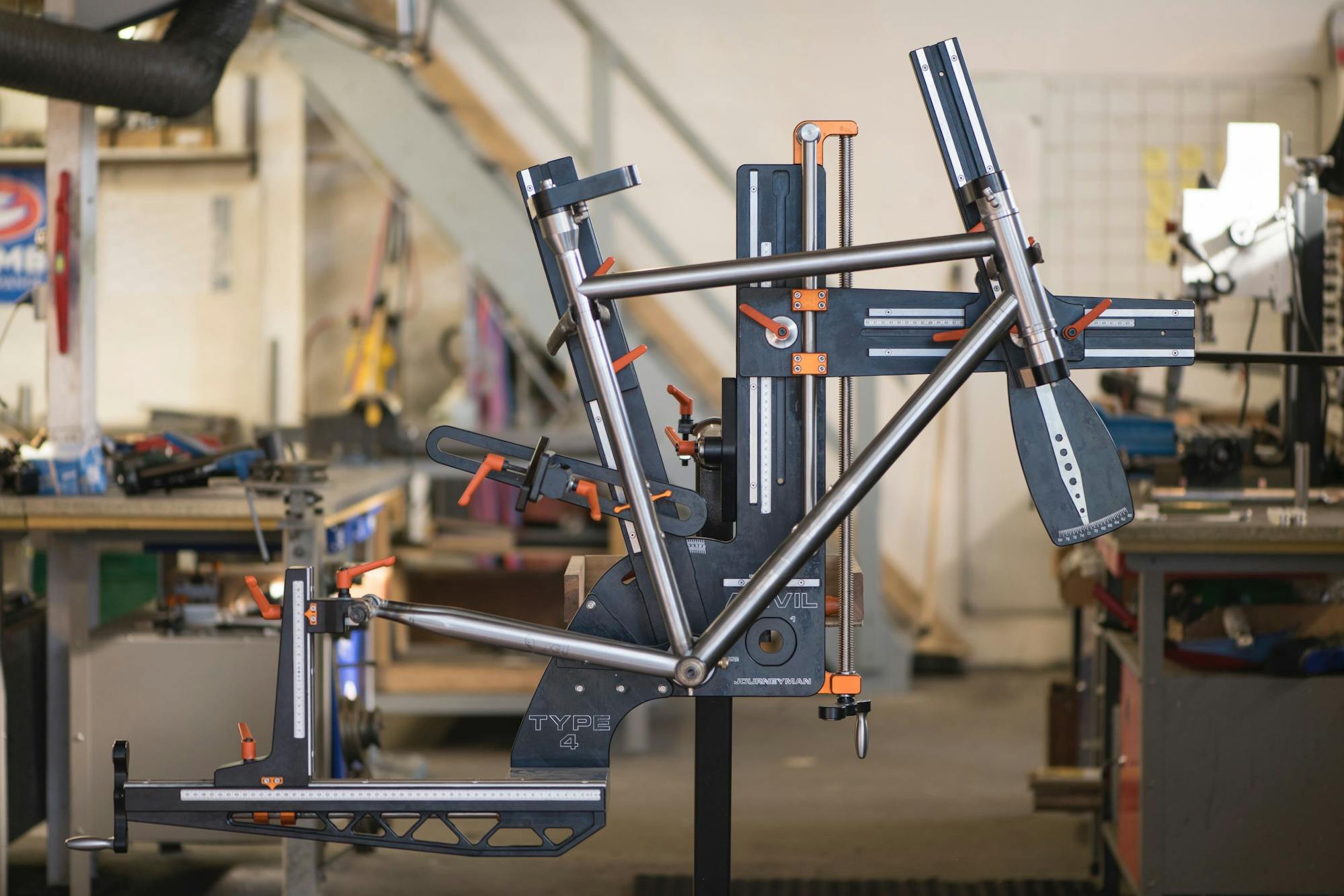

3. The manufacturing

Our workshop is a special place where we spend a lot of time, which we really like because it is where our know-how lives and where the commitment to excellence takes place. This is where your project will take shape.

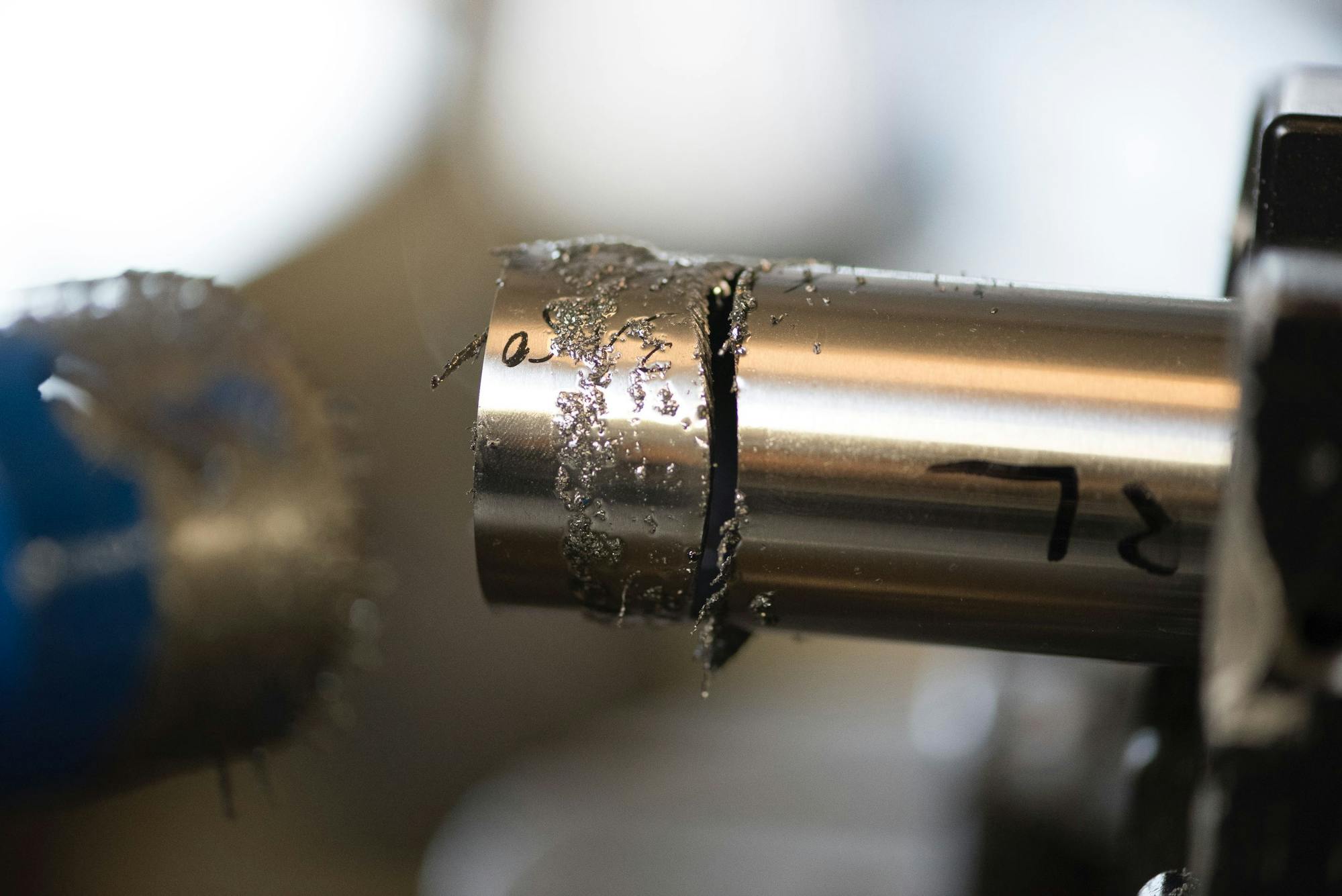

Each tube of your frame is first machined according to the geometry defined during the fitting session.

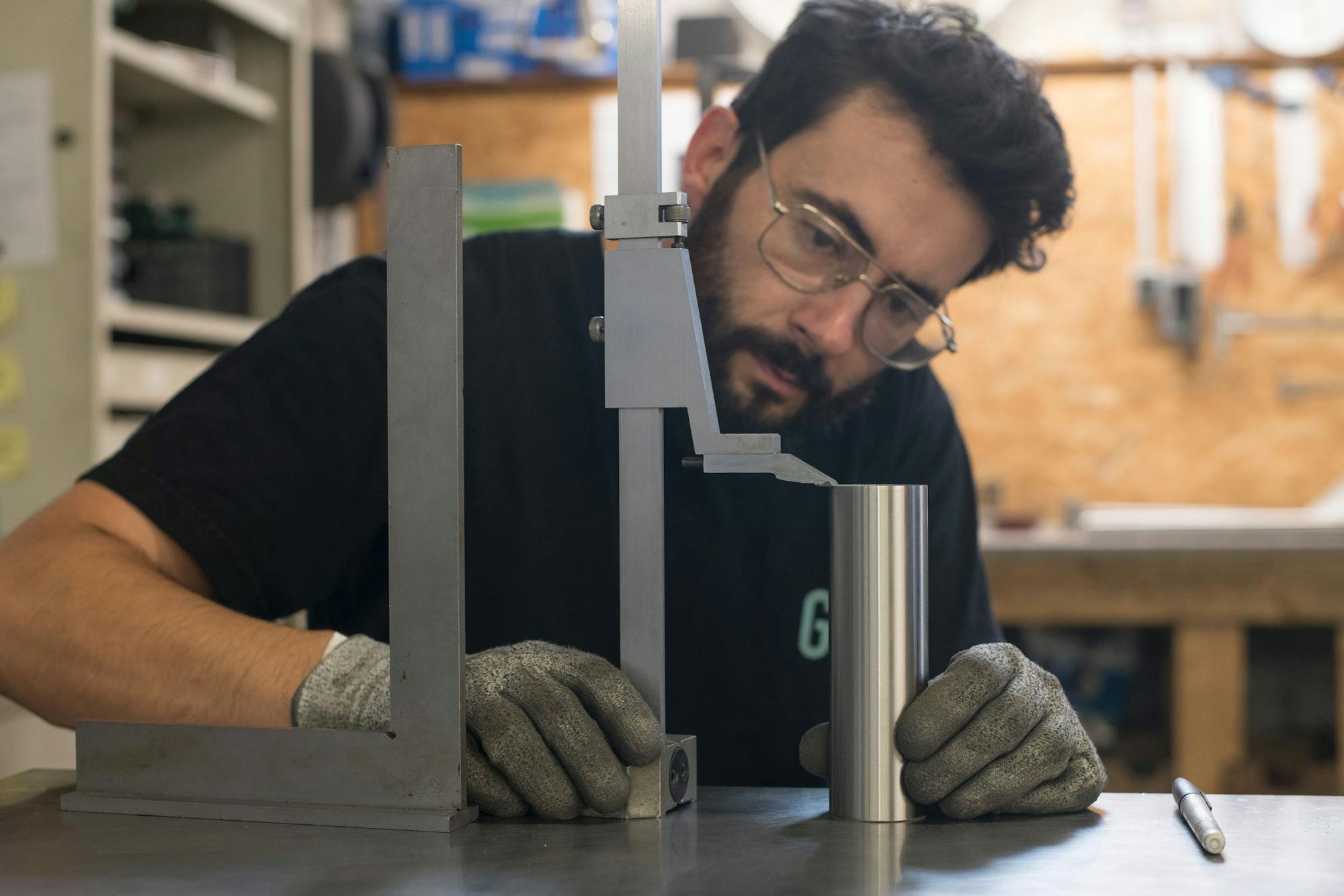

We adjust these cuts on a jig to the nearest tenth of millimeter, then we temporarily fix the tubes together with welding spots.

The frame goes onto the straightening jig to check for perfect alignment of the tubes and to correct possible distortions.

The frame builder then welds the tubes according to a specific sequence, which ensures dimensional stability for the whole assembly.

The frame's welds are then polished by hand. This step allows to eliminate the stress concentration phenomenon : if the welds are perfectly smooth, the stresses will be spread evenly throughout the assembly, which results in a stronger frame.

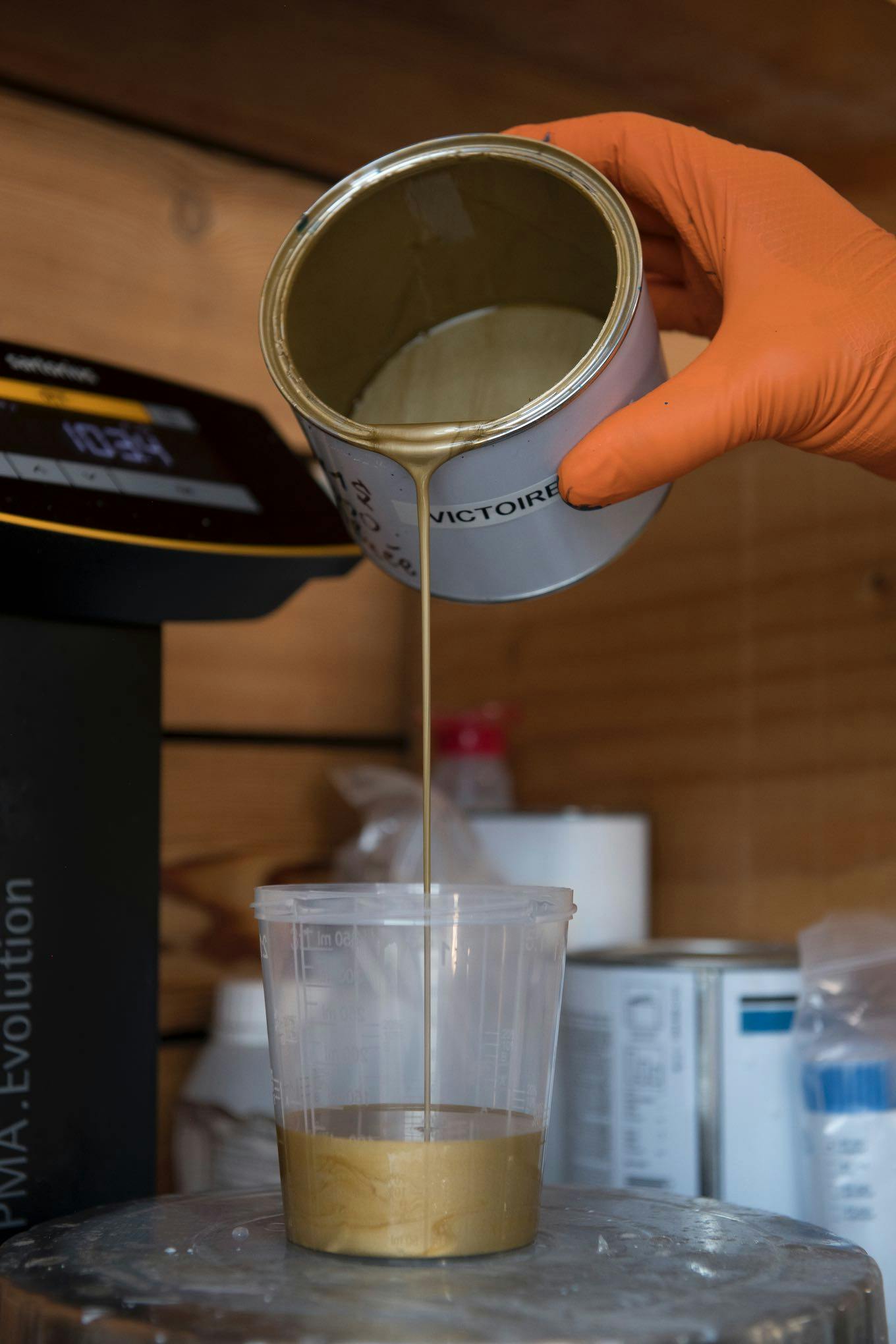

During one week, the frame is successively polished, cleaned, covered, prepared, covered again and painted several times, varnished and polished until it looks impeccable.

The bike's assembly generally takes one to two days. It is done by hand, following the parts manufacturers‘ guidelines and best practices, to ensure a long life to the components.

4. Bike delivery

We encourage you to come and collect your bike in Beaumont, in the presence of the people who brought your project to life. It is always a great experience to see your reaction while we unveil the bike. We are used to (when conditions allow it), to bring our customers on our favorite local roads and trails, and share with them the moments of their first ride on their new bike.

Curtains up in the showroom.

Ready to start ? Any questions ?

Contact-us

Things to know

12 to 18 months are required to deliver a bike, from the time of the project draft validation. (Please contact us if you want to know our current lead time). Since 2011, we built several hundreds bikes for our pleased customers. We are aware it is a long wait, but from experience we know that this is what it takes to complete a project the right way.

A custom-made bike costs 10 000€ minimum. Each bike requires between 70 and 150 hours of work, depending on how complex the project is. Also, our standards in terms of finish are as high as they get.

To add your name on the waiting list, a down-payment equal to 30% of the quote is required. Another down-payment of 50% will then be requested at the time of the fitting session, during which you will be given a timeline for your bike's completion. The remaining 20% will be due at the time of the bike‘s delivery. You will find more information in our terms and conditions.

For warranty and quality purposes, we only supply complete bikes, assembled in our own shop. Please contact us if you wish to include special parts that you own into your project.

Our frames are covered with a lifetime warranty against manufacturing defects. Our forks and stems benefit from a 5-year warranty. Components and accessories are generally covered by a 2-year warranty, except for Chris King components, which are covered with a lifetime warranty.

Paint touch-up, full checkup, complete restoration, replacement of tubes damaged in a crash, adding new features… These are just some of the services that we will be happy to provide, if needed. Please contact us for more info.

Interested in a handmade bike, but no need for custom?

You want a handmade bike, but don’t need it custom-made?

Distance is our new brand of ready-made, handmade bikes. Delivery time is less than 3 months and they are built using the same techniques and quality standards as Victoire. More info on Distance.bike.